Optical Bonding Technology

分類:科技新知&自然科學 2009/10/01 10:12

Optical Bonding

Technology

Where is it useful? • High Ambient lighting (Sunlight) conditions • Any situation where a Touchscreen is used • Any situation where a Protective cover is used • If the display has to be IP or NEMA rated (for protection from water, dust, etc) • If the LCD is vulnerable to mechanical shock or vibration • Where the display is operating at the high end of it’s market • How it works - Basic Principles 1

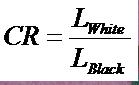

• CR = Contrast Ratio (typically >200:1)

• As referred to in LCD panel manufacturer spec sheets

• Really only applies to measurements taken in a dark room with no ambient lighting (reflections).

• Often does not take account of the angular distribution of light from an LCD panel

High Brightness LCD panel

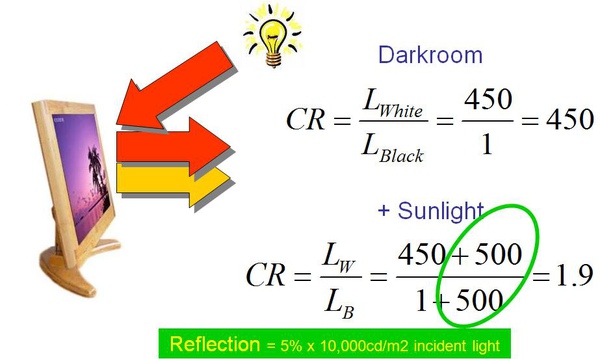

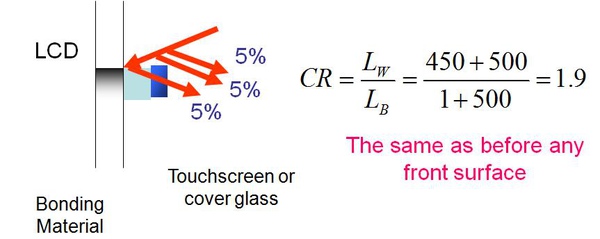

What about if a front surface is required?

• A front glass will have a large negative impact on the visible contrast

Includes Touchscreens, Anti-vandal glass, Privacy filter, moisture protection etc.

• Every interface (glass to air and air to glass) will lead to a reflection of about 5% of the light

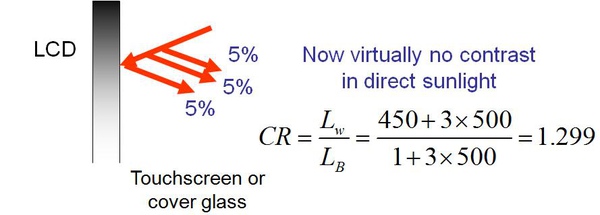

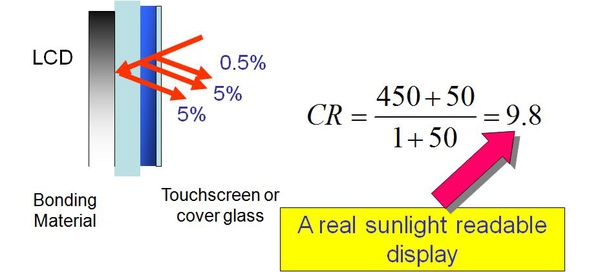

AR coatings

Using the bonding Solution instead

An additional layer of ‘bonding material’ effectively removes two of the reflective surfaces

Use AR coating and Bond together

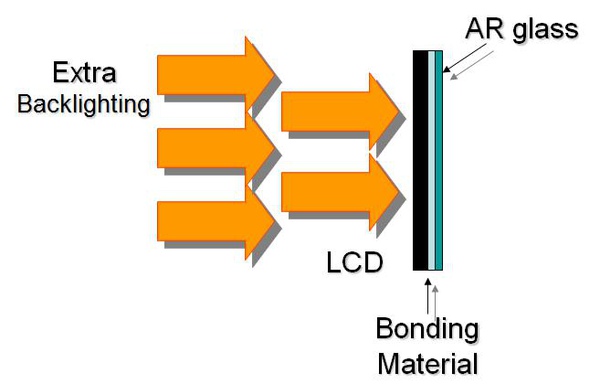

Sunlight Readability – Alternatives to bonding

• ‘Active’ brightness enhancement

– Causes Thermal issues (Clearing point of LCD panel)

– Increased power consumption

– Raises black level as well as White (inefficient)

• Simple AR coating (air gap or laminated)

– Reduces surface reflections but does not give ‘sunlight readability’

– Air gap can lead to greenhouse effect with solar loading (thermal issues)

– Inefficient use of AR treatment

Best Solution ?

Best current solution is a combination of all three. Addition of more backlighting power and bonding of optically enhanced glass

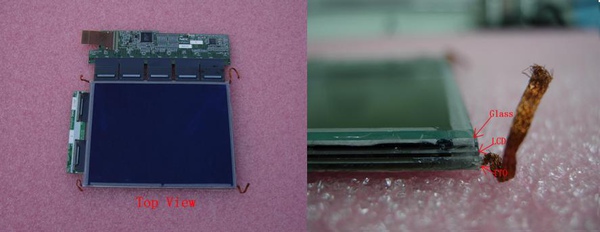

Ruggedization

Key mechanical / non-optical benefits of bonding

• Allows for fully sealed and mechanically toughened front surface with no optical degradation

• Increased resistance to shock and vibration for the fragile LCD glass component – due to bonding material itself.

• Removal of any risk of dust behind the front cover/touchscreen etc.

• Removal of screen front greenhouse effect

• Removal of the front screen condensation issue for sealed front covers

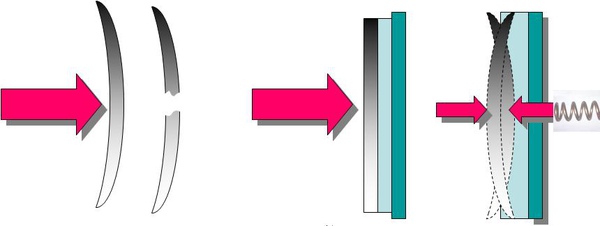

• Removal of parallax effect can enable new designs

Shock and vibration resistance

• Bonding material is jelly like, a perfect shock absorber

• Dampens any movement of the panel

Screen Contamination

• Dust and dirt

• Impair optical performance

• May require difficult cleaning operation even the removal of the touchscreen / front cover

• Screen front condensation during temperature changes

Bonding Technology

Bond Differentaiating factors

All the benefits of bonding +

• Cost effective

• Removable

• UV proven (5 year lifecycle)

• Fully scalable

• Large panel sizes

• Low toxicity environmentally friendly materials

• Can offer a bonded solution to fit most existing bezel openings (no re-design required)

• A Wide selection of options for the bonded surface

Providing Items

• Plain Glass

• AR glass

• Polycarbonate

• ITO EMI shields

• Any type of touch panel

OR

• Bond customer consigned materials

As a partner

• 30 years of experience in industrial displays

• Worldwide Manufacturing capability

• NO minimum order quantity

• Assistance in reducing the total cost of ownership

• Expert knowledge on panel and system selection

Complete Solutions

Examples:

Railways PID –Holland

Marine Displays

Theme Park

Bullring Shopping center 65” LCD Panel

Military

Tablet pc

Double layers bonding

Contact Person:

Mr. Frank Huang

Mobile: +886-988-238-989

email: frank88.huang@gmail.com

留言列表

留言列表

{{ article.title }}

{{ article.title }}